What is Aqueous Coated Paper Cups: An Eco-Friendly Innovation

The growing trend towards environmental sustainability has led to the emergence of innovative solutions in the packaging industry, including aqueous coated print paper cups. This article explores the concept of aqueous coated paper cups as an eco-friendly innovation that offers numerous benefits for businesses and the environment.

What are Aqueous Coated Paper Cups?

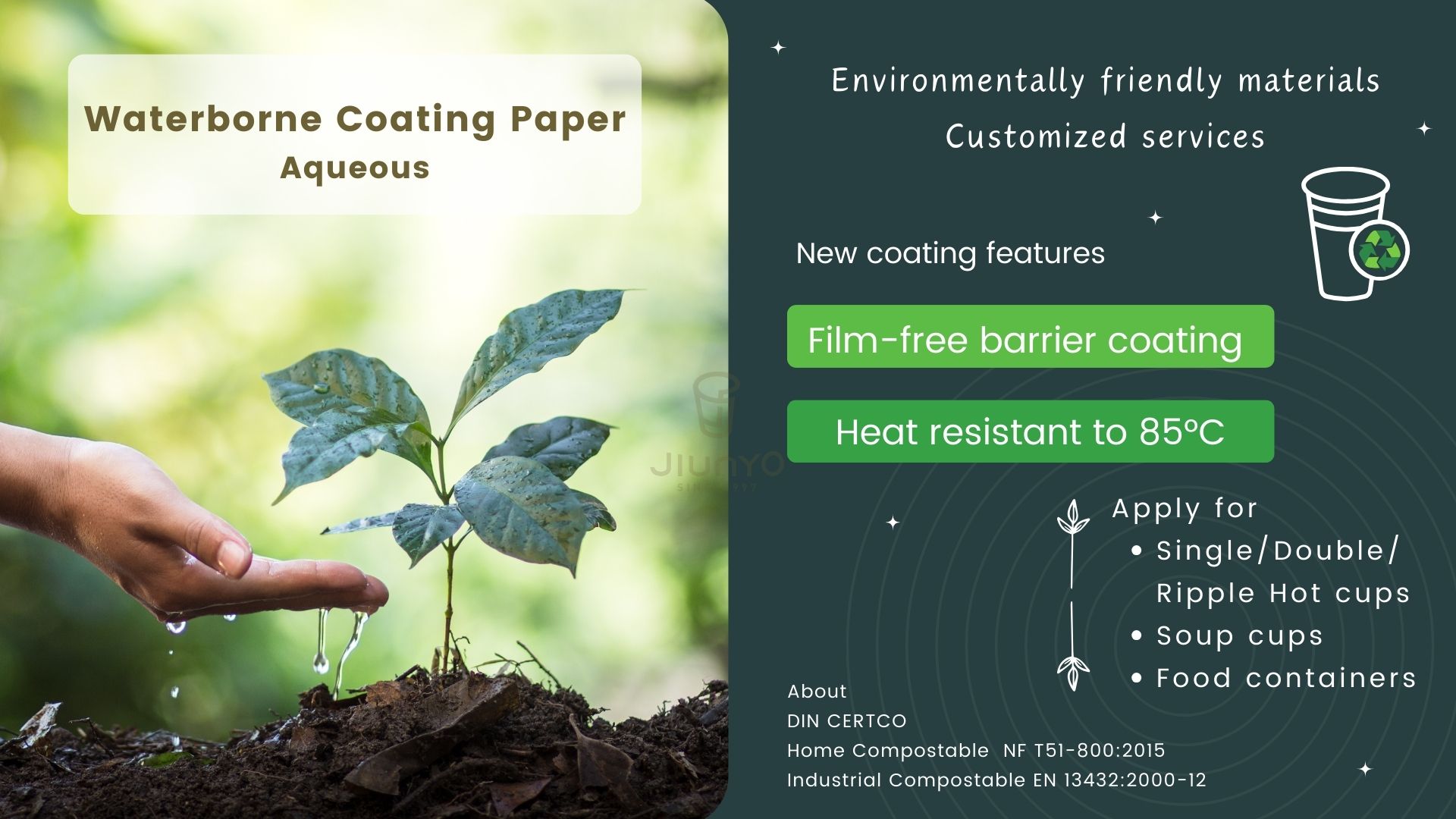

Aqueous coated paper cups, also known as water-based barrier coating or waterborne coated paper cups (WCP), or aqueous print cups, are eco-friendly packaging made from paper materials coated with a water-based solution. This coating enhances the cups' water resistance while reducing the need for traditional plastic coatings.

Paper cups with an aqueous coating are easily recyclable. After rinsing, they can be placed in any paper or cardboard recycling bin. Aqueous coated paper cups are plastic-free and can be directly recycled with paper. The aqueous lining is painted onto the paper and acts as a barrier for food packaging, making it useful for cups and other items containing fluids. WCP (Waterborne Coating Paper) was developed by Jiunyo and is a type of aqueous coating.

Difference between aqueous and non-aqueous coating

The main difference between aqueous and non-aqueous coating on paper cups lies in the composition of the coating and its application method:

Aqueous Coating:

What is an aqueous coating made of? An aqueous coating is a water-based mixture of water and additives applied to paper cups. It protects against moisture and scuffing and is environmentally friendly compared to non-aqueous coatings. Because the aqueous coating is thinner than other materials, it is easier to handle during recycling.

Non-Aqueous Coating:

The non-aqueous coating is solvent-based and offers better protection against moisture, grease, and abrasion than aqueous coating. However, the recycling process for non-aqueous coating is more complex. The coating cannot be easily removed from the paper cup, increasing recycling costs. Moreover, the lack of effective recycling and sorting practices among the public further complicates the issue.

The Production Process of Aqueous Coated Paper Cups

This process requires advanced expertise of developing raw materials and a thorough understanding of the market to ensure consistency and product quality. The production process of aqueous coated paper cups involves several stages, including:

1. Raw Material Selection

The first step entails the careful selection of raw materials. High-quality paperboard, typically made from wood pulp, is chosen for its strength and quality for food and beverage packaging. Additionally, aqueous coating materials such as water-based binders, pigments, and additives are selected based on their compatibility with the paperboard substrate and desired coating properties.

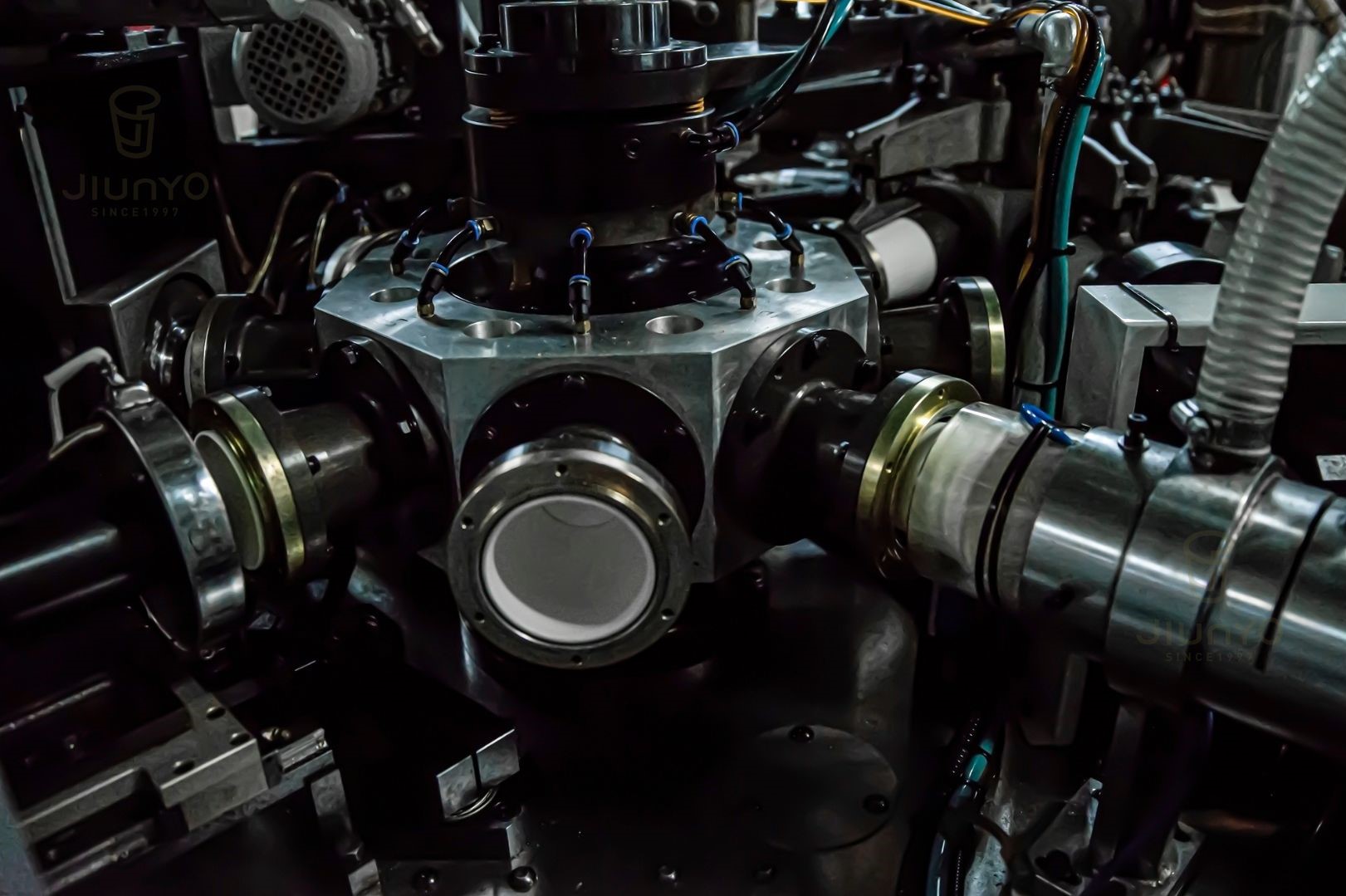

2. Coating

In this step, the selected paperboard is coated with an aqueous coating solution. The solution, composed of water, binders, pigments, and additives, is applied evenly onto the surface of the paperboard using coating equipment. The coating is very thin and uniform.

3. Printing

After the aqueous coating has been applied and dried, the coated paperboard is ready for printing. Flexography is used to apply decorative designs, branding elements, and product information onto the surface of the paperboard. Printing is typically performed using multiple colors to achieve vibrant and eye-catching graphics on the paper cups.

4. Cutting

Once the printing process is complete, the printed paperboard sheets are fed into cutting equipment. Precision cutting machines cut the paperboard sheets into individual cup blanks of the desired size and shape. Cutting ensures that each cup blank is accurately sized and free from defects or irregularities.

5. Forming

This step requires precise production conditions to provide high-quality and consistent results. The cut cup blanks are transferred to cup-forming equipment. The machine shapes the cup blanks into three-dimensional cups by folding and sealing the edges. The formed cups may undergo additional processes, such as rim rolling or heat sealing, to reinforce the cup structure and ensure leak-proof seals.

6. Quality Inspection

Quality inspection is conducted at various stages throughout the production process of aqueous coated paper cups to ensure their integrity and consistency. The inspectors examine raw materials, coating application, printing quality, cutting accuracy, cup forming integrity, and product appearance to identify any defects or deviations from quality standards. These are then addressed promptly to maintain product quality and customer satisfaction. Tests also include resistance to hot water and coffee confirming their durability and performance. After inspection, the cups are packaged and shipped to businesses.

Why Businesses Should Choose Aqueous Coated Paper Cups: The Advantages

1. Biodegradable

Aqueous coated paper cups are plastic-free, recyclable, and biodegradable, reducing environmental impact and promoting sustainable practices. They are made from paper, which is a renewable resource. The coating is free of harmful chemicals and safe for food and beverages. It is a newly developed material meeting the increasing consumer demand for sustainable products. It indicates a future trend and can help businesses remain competitive. Moreover, choosing eco-friendly packaging reflects positively on a business' brand image. This attracts environmentally conscious consumers and fosters loyalty.

2. Repulpable

Aqueous coated paper cups use a biodegradable water-based coating technology instead of the traditional plastic lining. The coating is absorbed into the paper fibers, while plastic linings are applied on the outside of the paper. These cups can be recycled as regular paper because they don't require delamination. This major advancement promotes environmental friendliness by facilitating recycling, reusing, and reducing waste, while also helping to reduce carbon emissions. The paper mills can re-pulp and reuse these paper cups, which can be applied to non-food products.

3. Safe and Non-Toxic

Aqueous Coated Paper Cups are safe and non-toxic because they use water-based coatings free from harmful chemicals like BPA, Plasticizer, and other toxins. Therefore, you don’t need to worry about contamination from harmful chemicals. They are safe and suitable for food and beverage contact. Furthermore, the aqueous coating provides excellent waterproofing, ensuring that the cups remain intact and functional even when exposed to liquids. They also provide good breathability, making them a good choice when breathability is required.

Advantages of Jiunyo's WCP (Waterborne Coated Paper Cups)

1. Lightweight and Thinner

The WCP coating developed by Jiunyo is lightweight and thinner than conventional coatings, supporting waste reduction efforts and other eco-friendly principles. This innovative technology showcases advanced product design features that distinguish it from other coatings on the market.

2. Diverse Applications

Jiunyo is dedicated to developing aqueous coatings for various paper containers. Given the company's production of multiple paper container types, we continuously innovate to apply aqueous coatings across different products. Currently, these coatings can be used on soup, coffee, double-wall, corrugated, and tea cups.

Aqueous Coated Paper Cup Is the Eco-Friendly Option You’re Looking For

Altogether, aqueous coated paper cups offer a sustainable solution for businesses seeking eco-friendly packaging alternatives. By adopting these cups, businesses can demonstrate their commitment to environmental responsibility, meet consumer demands, and contribute to a greener future. We encourage businesses to embrace aqueous coated paper cups as part of their sustainability initiatives. For high-quality aqueous coated paper cups and eco-friendly packaging solutions, choose Jiunyo!

Jiunyo's WCP is a water-based and eco-friendly coating paper cup. It is polyethylene-free and recyclable. It's suitable for single-use beverage and soup cups, hot cups, and food containers. It's also certified compostable to EN 13432:2000 Din Certco standards. As a professional, aqueous coated paper cup manufacturer, Jiunyo is dedicated to providing high-quality products and services to customers. Want to know more about aqueous coated paper cups? Please do not hesitate to contact us if you require further details or technical support.